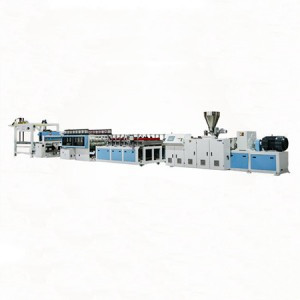

PLA Sheet and Forming Machine

ⅠMain Parameter

SJΦ63*2/Φ130 PLA Foam Sheet and Forming Machine

| Item | ||

| 1 | Capacity | 200-250kg/h |

| 2 | Sheet width | 640 mm-1100 mm |

| 3 | Sheet thickness | 1mm-3mm |

| 4 | Total Power | 180 KW |

| 5 | Water Consumption | 6 ton / h |

| 6 | Equipment Floor Area | 29*6 m |

| 7 | Extrusion Line Weight | 18 ton |

| 8 | Bubbling Times | 5-15 times |

Ⅱ Machine List of the Line

|

1 set |

|

1 set |

|

1 set |

|

1 set |

|

1 set |

|

1 set |

|

1 set |

|

1 set |

|

1 set |

|

1 set |

|

1 set |

|

1 set |

Ⅲ Specific technoloy parameter

- 1.Mixing machine & drying machine

| Machine frame material | Weld by structural steel |

| Feeding tube material | Weld by stainless steel |

| Mixing way | Vertical mixing |

| Mixing capacity | 500 kg / per time |

2.Feeding machine & Hopper

| Motor power | 1.5 kw Frequency converter precise speed control |

| Control system | Stress fracture automatic alarm system |

| Automatic feeding system | Feeding capacity 300kg/h , motor power 2.2 KW |

| Function of hooper with mixing device | Mixing and avoid caking |

- 3.First -level double screw extruder

3.1 Power device

| Main motor | Simens , 90KW , with cooling device |

| Gear box | Special for double screw extruder with cooling device |

| Adjust way | Frequency control |

3.2 Extrude screw

| Extrude Diameter | Φ 63mm , double screw |

| Material | 38CrMoAIA , Nitrogen Treatment |

| Hardness | HV900-1000 |

3.3 Extrude barrel

| Inner Diameter | Φ 63mm |

| L/D | 1:40 |

| Material | 38CrMoAIA , Nitrogen Treatment |

| Hardness | HV900-1000 |

3.4 Heating and cooling way

Adopt cast aluminium and high precision thermistor temperature

Extrude barrel cooling by water , using independent water circulation system

3.5 Screen changer device

Model of 150 , slide type , double holes , hydraulic driver , gear pump , motor power 3kw

- 4.Union pipe

| Inner diameter | Φ 63mm |

| Out diameter | Φ 100mm |

| Material | 38CrMoAIA , Nitrogen Treatment |

| Hardness | HV900-1000 |

| Heating ring | Stainless steel |

- 5.Second-level single screw extruder

5.1 Motor device

| Motor | Simens , 380V , 50HZ , 75KW , with cooling device |

| Speed adjust way | Frequency control , with cooling system |

5.2 Heating cooling way

Heating : Adopt cast aluminum heater , motor power 6kw / group

Nine group temperature control , RKC automatic temperature control system

Cooling : water cooling , install solenoid valve on the cooling pipe , with cooling water tank

- 6.Die head

| Material of die core rod | 38CrMoAIA , Nitrogen Treatment |

| Hardness | HV900-1000 |

| Fan power | 750 W |

- 7.Cooling and cutting device

7.1 Machine fram is welded by structural steel and steel plate .

7.2 Moded cylinder is welded by steel pipe , diameter is determined by sheet width .

7.3 Cooling fan is welded by steel plate , diameter is determined by sheet width .

7.4 Power of central blower high pressure machine 1500 W

7.5 Open mode : 10P cooling machine 1 set , cooling fan 1 set

8.Haul-off machine

8.1 Hall-off roll - 2 pieces diameter: Φ420mm , width 1300mm ;

8.2 Pressure roller -1 piece diameter: Φ130mm , width 1300mm ;

8.3 Pressing cylinder 1 set

8.4 Steel guide roll 2-pieces , diameter Φ74mm , width 1300mm

8.5 Motor power 3kw

8.6 Velocity 0-30m / min

8.7 With static electricity canceller

- 9.Winding machine

9.1 Machine fram is welded by structural steel and steel plate

9.2 Winding roll 2 set , circular arc panel , can stretch out and draw back , winding roll diameter 270mm , valid width 1300mm

9.3 Guider 1 set , diameter 175mm , valid width 1300mm

9.4 Telescopic cylinder 1 set

9.5 Torque motor 2 set , torque 16N , torque contral

9.6 With static electricity canceller

- 10.Foaming agent injection pump

10.1 Substrate is casted by Q200 , natural ageing treatment

10.2 Ceramics plunger pump , route of plunger pump can be adjusted

10.3 Explosion -proof electric machine

10.4 With metering control system , 0-20L /h (infinitely variable control system ), nominal pressure 25Mpa

10.5 Structural style : worm speed reducer , N shaft driving

- 11.Electricity control cabinet and electricity parts

11.1 electricity control cabinet is made by steel with cooling fan

11.2 Inverter ( famous brand )

11.3 Breaker , relay (LG)

11.4 Temperature control sysyem ( RKC )

11.5 Other electricity parts ( famous brand )

- 12.Cooling Frame

Valid width 15m , length 5m .

- 13.Finished products