SMC Machine

Ⅰ. Main techincal parameter

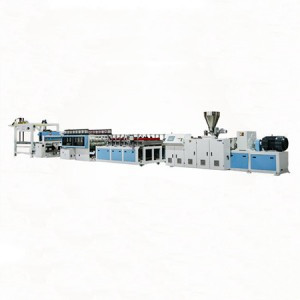

SMC 1000B Sheet Molding Compound Panel Production Line

| Max width of SMC sheet | 900mm |

| Density of SMC sheet | 2-5kg/m² |

| Resin paste viscosity | 10000-25000 mPa.s |

| Fiber content | 12%-35% |

| Blade driving motor | 380V/50Hz, 1.5KW |

| Blade driving motor speed | 20-195r/min , can be adjusted |

| Mesh belt speed | 5-15m/min , can be adjusted |

| Mesh belt width | 1050mm |

| Length of impregnation section | 3300mm |

| Roller quantity | 19 pairs |

| Max output | 2500kh / hour |

| Total power consumption | 5 kw |

| Outline dimension | 8500mm *190mm*2400mm |

| Total weight | 4000kg |

Ⅱ Main Parts for the Production Line

(used for the compounding, compaction and packing of SMC sheet) |

1 set |

(for the delivering and mixing of resin paste, thickener, pigment paste ) |

1 set |

|

1 set |

| 4. Pneumatic diaphragm pump (2 inch American brand) (for resin and low shrinkage delivery) Including pipes and valves | 2 set |

| 5 . filler elevator (for the conveying of filler to the mixing barrel) | 1 set |

6.Fiber content 12%-35% adjustable, error ±1%.

7.The running speed of mesh belt shows the current mechanical running meter per minute. Running speed can be adjusted on the touch screen.

8.Main drive roll with skid strip to avoid the skidding of mesh belt. Running speed of mesh belt is 5-15 meters/minute,can be adjustable. Assemble the automatic rectifying function of PLC mesh belt, ensure the normal and reliable operation of the mesh belt in production

9.The highest production speed is 2.5 tons per hour when the tensile strength of the film is achieved .China made drive reducer ,3kw Variable frequency drive motor.

10.The rollers in the impregnation section ≥ 39 pcs(Main drive roller 2pcs, upper and lower dipping roller 39pcs, mesh belt up tight roll 4 pcs) Compaction cylinder 10pcs.

11.Chopped fiber cutter frame 1 set,motor 1.5kw, minimum cut length for fiber is 25.4mm。The thread tube is 32sets. High precision cutter roller can guarantee cutting quality and extend the service life of blade and rubber roller.

12.Installation of glass fiber dispersing device, make the glass fiber distribute evenly on the resin paste in the shape of net.

13.Sheet production speed can be adjusted by two buttons at any time and keep the same fiber content.

14.Installation of 2pcs film flattening roll, 2 sets of brake system to make the film enter into the scraping paste area without wrinkle and make sure the paste material evenly on the film. There are places for the spare film on the upper and lower rack.

15.Doctor blade assembly can be pneumatic lifted to make it easy to be cleaned after the production, the gap adjustive error between scraper and base plate≤ 0.05 mm. The function of quick lift of the scraper can prevent the film from being cut by the particle in the resin paste.

16.Electric crane will be installed on the upper trough for changing the film to install the spare film quickly, to ease of work intensity

17.All rollers’ surface of unit are coated or chrome plated.

18.Electrical Control: Electrical control cabinet with machine. 10 inch colorful touch screen. PLC, frequency convertor , will be Mitsubishi brand. Circuit breaker, contactor,small relay will be Mitsubishi brand (Japan),Other parts will be China well-known brand. Power is three-phase four-wire system,440v,50hz.

Ⅲ Online feed system 1Set

(for the delivering and mixing of resin paste, thickener, pigment paste )

1)Out size 1600mm*350mm*500mm

resin paste metering pump(A pump) 1 set, NETZSCH brand pump, SEW drive motor, with motor power of 3 kw, 440v, 50hz and the max. flow of 2 cubic meters per hour.

Outer dimensions:(L*W*H) 1600mm*350mm*500mm

2)thickener metering pump(B pump) 1 set

U.S. original imported VIKING pump, China made driven reducer, Siemens frequency converted motor, 0.75kw, 440v,50hz.

Outer dimensions:(L*W*H) 800mm*300mm*300mm

3) . Out size 800mm*300mm*300mm

Pigment paste feed pump(C pump) 2 sets, U.S. original imported VIKING pump, China made driven reducer, Siemens frequency converted motor, 0.75kw, 440v,50hz.

2 sets of pigment paste feed pump will be installed on the working table with containers and pipes. When operating, use 1 scale and 1 container, and the other scale as standby application. Install an electrical transfer switch on the electric box to control the working of the appropriate pigment pump, then color can be changed quickly, and to avoid cleaning the pump and container C each time.(The container not used can not be put at the site when operating, avoid mis-adding of the pigment paste. When changing color, replace the container on the scale.) (In few days, not using pigment paste is ok, but after longer time, there will be sediment which effect the pump speed and life, the high temperature in Dubai will also effect the production. So, not do cleaning within 3 days is ok. Longer than 3 days, workers need to do the cleaning.)

4)Out size 500mm*600mm*3150mm

Online mixing assembly 1 set, power of motor 4kw, 380v, 50hz, China made explosion –proof motor, total height 3150mm

Outer dimensions: (L*W*H) 500mm*600mm*3150mm

5)1200L resin paste storage tank 1 pc

with removable rimmed lid

the lid should be in 2 pieces with a hinge in the middle to be able to uncover part of the container.

We suggest your abandoning this type of lid, it will inconvenient for you to check, clean and add the material.

Outer dimensions:(L*W*H): 1500mm*1300mm*1200mm

6) 2400mm*750mm*850mm

Pigment, Mgo paste storage tank 3 pcs

with removable rimmed lid

the lid should be in 2 pieces with a hinge in the middle to be able to uncover part of the container.

We suggest your abandoning this type of lid, it will be inconvenient for you to check, clean and add the material.

7)There will be electronic scale at the bottom of A.B.C container sending the signal to PLC, PLC controls the speed of motor by calculating to get our set value, and send signals when the material in the container is about to finish, to inform the worker to add material, by turning on a speed following switch in the online mixing system (ABC systems will work according to current speed) . After feeding the material, the switch will turn off and the system will automatically adjust the output value because there is pressure change. If the material is not added in time, the system will test the pre-set empty value, then stop the online mixing system. When the container is filled up to the max. value, system will also warn and send signal to inform stopping adding material. And if there is no material in the container, the machine will stop.The online mixing system can be restarted after the addition of material.

8)Automatic control distribution cabinets 1 set

Outer dimensions:(L*W*H) 600mm*700mm*1200mm

Including 4 sets of frequency inverters, PLC, 10 inch color touch screen display, Mitsubishi brand

the control numerical of separate output weight per min for ABC pump will be shown on the display

motor of mixer will show the speed per min.

circuit breaker , contactor and small relay will be with Schnelder brand or Japanese brand

9)Stainless steel feed piping 1 set

Packing size(L*W*H): 3000mm*300mm*300mm

(15 pieces flexible metal tubes, 15 sets of quick connection joints, 20 sets flat sealing gaskets)

10)1.05*1.05m electric weigh 1 set

(for A storage tank), small electronic scale 3 sets (for B,C storage tank) . It was considered of using 2 sets of scale on C storage tank, but 2 scales can not be connected to PLC or connected via shift switch at the same time(pumps can be shifted via shift switch)so it is suggested to use 1 scale on C pump. Put the storage tank on the scale accordingly on the pump which will be used. In this way, pigment paste will be added correctly, otherwise

Ⅳ 30KW high speed dispersion machine 1 set

(mixing equipment for making resin paste)

1.Spindle motor 4P,440v,50hz, 22kw explosion-proof motor.

to adjust the speed by inverter, the max. speed will be 1450rpm/min

2.The max speed of main axle will be 1200r/min

to control the hydraulic pump and hydro-cylinder by button to make the main axle up and down. motor of hydraulic pump 4P, 440V,50hz, 0.75 kw explosion-proof motor

3.Stainless steel dispersible plate with dia of 300mm.

4. 4pcs mixing barrel with dia of 700mm, with height of 700mm, with 4 wheels at the bottom, with ring at the side

Discharging valve is at the bottom, the opposite of the pushing handle

There are two types of valve, stainless steel ball valve and valve made by our factory. The stainless ball valve can be sealed well, but difficult to be opened and closed. And the self-made valve can be open and closed easily, if it is not cleaned well or not cleaned for a long time, there will be a little leakage

5.Control apparatus for control supply, main axle inverter, hydraulic lift control.

ⅤPneumatic diaphragm pump 2sets (2 inch American brand) (for resin and low shrinkage delivery)

Including pipes and valves

Ⅵ filler elevator 1 set

(for the conveying of filler to the mixing barrel)

Main motor 4P, 440v,50hz, 3kw, explosion-proof motor, cycloidal reducer

stainless steel lifting barrel and innter core

Stainless steel material hopper

with powder propeller, 0.75kw motor (Ordinary Siemens)

with delivery hose joint with dispersion machine

Ⅶ SMC production accessories

Stainless steel feed groove 1PC 2000*120*120mm(L*W*H)

Blade 60pcs,Spacer 40pcs.

A set of tool with machine